Advanced Manufacturing

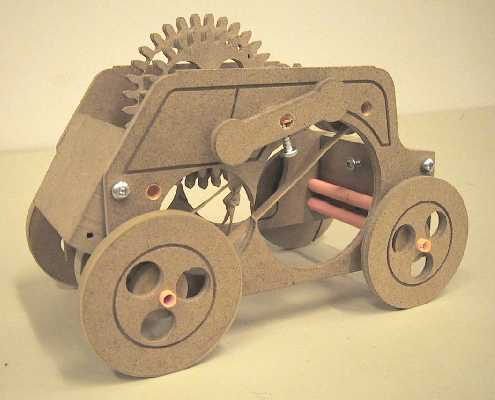

MasterCAM/CNC Machining Project

Please consult with your Project Outline on D2L to

see what exactly you will be getting in your parts kit.

Note: Parts may be substituted, depending on what's in the Mech office supply cabinet

1/4" dia. X 12" wooden dowel = 6g

Paper Clips

3-3/4" long when stretched out

wire is 0.035" dia.

Rubber Bands

3" when not stretched

will safely stretch to 12"

K= 1/2 lbf/inch or K= 0.8 N/cm

coefficient of friction on tile floor about u=0.9

Wax birthday cake candle

approx. 2-1/4" long

Medium Density Fiber (MDF) board

(MDF is a wood pulp product)

Boards - 7"x4"x1/4" thick (nominal)

= 96g

#6-32 x 3.4" long machine screw with nuts 2.4g

Not shown:

Sheet of 8.5 x 11" white paper

Power Sources

Constant Force Spring

5 lbf

- weight = 36g

5/8" wide, 1.13" OD

McMaster- Carr #9293k337

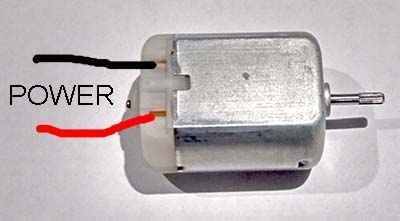

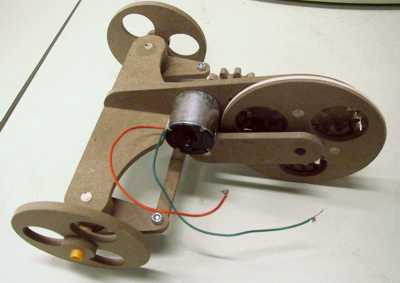

Small DC electric motor (previous year)

motor dia. = 0.730x0.950"

motor body length (not including shaft) = 1.360"

shaft dia. = 0.081"

shaft length from motor = 0.385"

Specs: no load 10,000rpm @ 12V

no load: 100mA and 1.2W

stall (0rpm): 3.6A and 43W

Torque at stall = 0.02Nm

(you must make your own MDF or rapid prototyped pinion gear)

NOTE:

Power must be applied to the two "sockets",

so allow space for wires as shown below:

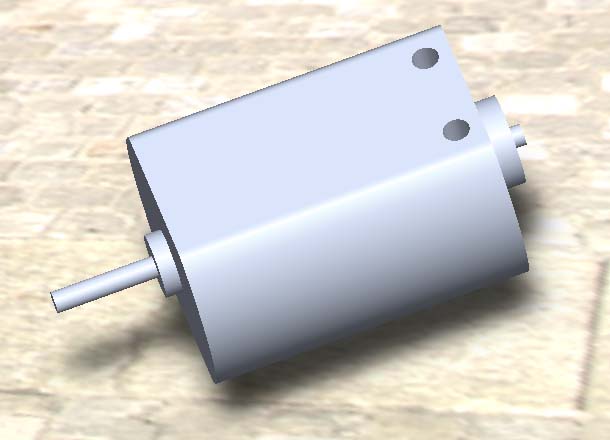

SolidWorks File

SolidWorks Part file of the motor

Fitting Parts Together

The milling machines you will be using are accurate to within a few

thousanths of an inch.

Generally, if you need a 0.250" dia. shaft to rotate in a 0.250" hole,

draw a 0.250" hole in AutoCAD,

bring the drawing into MasterCAM, generate G-code and the machine will

cut an exactly 0.250" hole.

If you want a press fit, machine a hole 0.002" smaller, if you want a loose fit, machine a hole 0.002" larger. Keep in mind, the dowel's dia. changes with temperature and humidity.

Remember, small holes can be filed (or sanded) larger.

You can't make a big hole smaller!

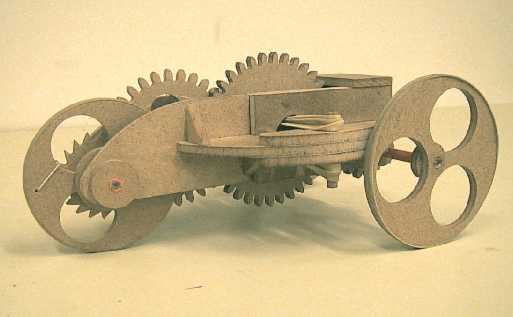

Mounting the Motor

The motor can be press fit into the body.

Machine a hole

in your car body for a press fit.

Close-up of motor mount.

Designing Gear Trains